PLCS Limited’s unique corrosion protection solutions, based on a modern polymer technology, are designed to protect transmission pipelines, including oil, gas, water, utilities, and district heating systems.

Steel piping is typically supplied with a factory-applied protective coating, but the ends of each length are left unprotected to permit joining. PLCS Limited’s corrosion protection solution covers the unprotected join. Supplied as a kit, PCLS Limited’s solution consists of a heat shrinkable patch, ready cut to size, patch adhesive (if required), and a special closure patch. Following welding and testing, the joint surface is prepared, the heat-shrinkable patch wrapped around and shrunk to size, and the closure patch is applied to complete the seal.

Covalence Pipeline Heat Shrinkable Products

Covalence Pipeline Heat Shrinkable Products

Various types of heat shrink sleeve products installed on a range of different pipe materials, illustrating the versatility, and range of material available from PLCS.

HTLP80 heat shrink sleeve joint protection system, is subjected to stringent quality assurance testing, in accordance with the clients field weld joint inspection coating procedures.

Suitable for pressurised systems

PLCS Limited’s corrosion protection is suitable for pressurised systems, and can be relied upon in extremely hostile environments, including the sea bed, where oil pipes, in addition to constant immersion in salt water, may need to withstand internal temperatures of up to 100 degrees centigrade. Installed on oil rigs, and subject to abrasion by the waves, PLCS Limited’s heat shrinkable materials provide protection for up to 100 years.

PLCS corrosion protection can be relied upon in extremely hostile environments

PLCS corrosion protection can be relied upon in extremely hostile environments

Anaerobic Internal Mainspray Treatment

The equipment is fed into the pipeline until the built-in sond locates a joint, then a low viscosity sealant is applied, through a specially designed spray head, with pin-point accuracy. The sealant penetrates the joint, and cures anaerobically to provide a cost-effective repair.

Anaerobic Internal Mainspray Treatment

Anaerobic Internal Mainspray Treatment

Technical and engineering advice

PLCS Limited’s technical sales and support departments offer technical and engineering advice to help solve your specific corrosion protection problems, or hands-on field training, to allow your own staff to perform installation a full installation service, if required.

PLCS Limited is constantly working to anticipate our customers’ needs in an ever changing and competitive environment.

Field weld joint applications utilising heat shrink sleeve technology

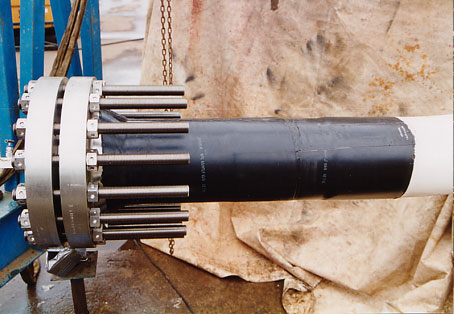

WPC100M heat shrink sleeve system installed, by PLCS contract division, to polypropylene coated field weld joint. Sub-sea elevated temperature pipeline (100°C max)

WPC100M heat shrink sleeve system installed, by PLCS contract division, to polypropylene coated field weld joint. Sub-sea elevated temperature pipeline (100°C max)

WPC100M heat shrink sleeve system installed, by PLCS contract division, to fusion bonded epoxy coated, to concrete weighted, transition field weld joint. Sub-sea pipeline tie-in connection.

HTLP60 three layer heat shrink sleeve system installed, by PLCS contract division, to welded field joints to afford corrosion protection during, and on completion of the pipe insertion in the directional drilling operation.

WPCZ heat shrink sleeve system installed, by PLCS contract division, to concrete weighted field weld joint. Sub-sea pipeline tie-in connection.

WPC100M heat shrink sleeve system installed, by PLCS contract division, to polypropylene coated duplex stainless steel line pipe, with field welded flanged joint. Sub-sea pipeline tie-in connection.