PLCS Limited is a world pioneer in the development and installation of gas escape control products, designed to permanently repair all types and sizes of gas distribution pipe.

Once a gas escape is detected, typically following reports from the public, speed of response is vital. PLCS Limited offers a range of leakage control solutions designed to provide a fast, permanent repair that meets national and European permanent gas repair standards, and will seal the pipe for up to 50 years.

High pressure pipe repair

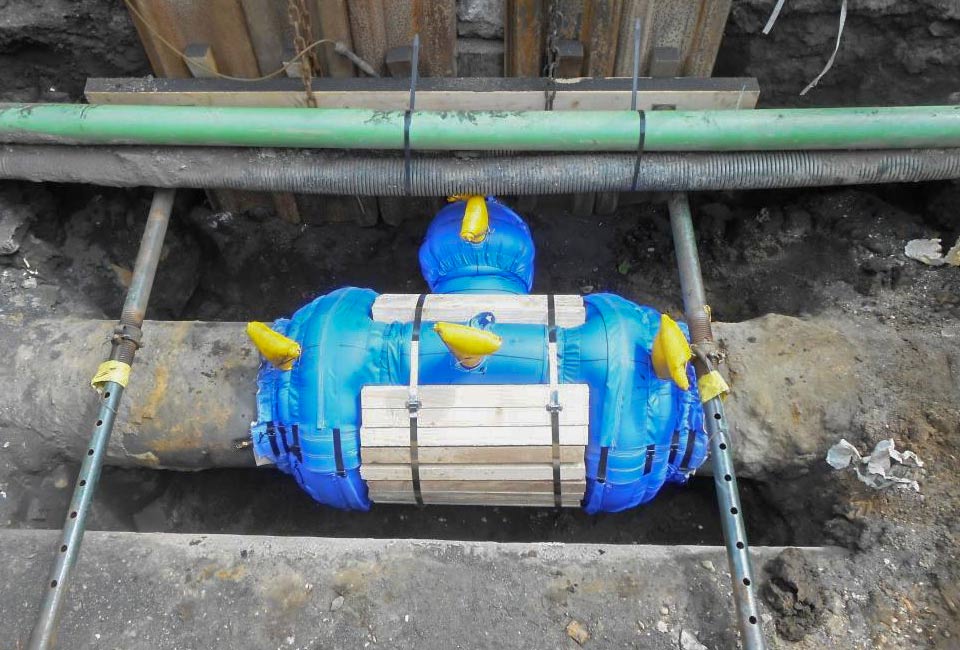

For high pressure pipes, PLCS Limited offers an encapsulation solution, consisting of a sleeve of mould of metal or fabric filled with a resin sealant. The leaking joint, valve or t-piece, is cleaned and primed, and the mould applied and filled with resin. The resin is then pressurised, manually in the case of a fabric mould, using compressed air in the case of a metal mould, until the pressure exceeds that of the escaping gas, and the resin cures to a provide a permanent, flexible seal. The pipeline can be reburied after 6 hours.

Repair case installed to be filled with encapsulant

Repair case installed to be filled with encapsulant

Low pressure pipe repair

For low pressure pipes, PLCS Limited offers a choice of two heat-shrinkable leakage control solutions. For larger diameter pipes, including external domestic supply pipes, our unique Rayseal electrically-shrinkable patch is fast and convenient. Once applied to the leaking pipe, the Rayseal patch is connected to an electrical supply and electrically heated for the appropriate length of time, until the material shrinks to provide a permanent repair. The pipeline can be reburied once the seal has returned to ambient temperature. For smaller diameter pipes, such as internal domestic supply pipes, PLCS Limited offers a GRSM heat-shrinkable patch. The leak, typically on a threaded joint, is sealed with putty, the heat-shrinkable patch is wrapped around the joint and shrunk with a hot air gun, and the repair is finished with a metal closure.

Kit demoulded to show Cured Flexpress repair

Kit demoulded to show Cured Flexpress repairCall in the specialists

Since gas escapes must be repaired in a live system, and often in inconvenient locations, including public streets where safety is paramount and disruption must be kept to a minimum, repair work must be performed by specialists working under gas conditions, using the appropriate safety equipment, and with the appropriate management systems in place. PLCS Limited’s leakage control team covers the entire country and works with all the gas network companies.

PLCS Limited’s technical sales and support departments offer hands-on field training, to allow your own staff to perform repairs a full repair service, performed to national and European permanent gas repair standards, and guaranteed for 50 years.

Types of joint repair

Encapsulation low pressure gas joint repair kit fully approved to BGC/PS/LC8 part 1 and the DVGW European standard for the permanent repair of distribution gas joints operating at pressures up to 170m/bar.

Encapsulation semi medium pressure gas joint repair kit fully approved to BGC/PS/LC8 part 1 and the DVGW European standard for the permanent repair of distribution gas joints operating at pressures up to 0.75 bar.

Encapsulation medium pressure gas joint repair fully approved to BGC/PS/LC8 part 1 and the DVGW European standard for the permanent repair of distribution gas joints operating at pressures up to 2.00 bar.

Encapsulation special pipe fitting repair kit fully approved to BGC/PS/LC8 part 1 and the DVGW European standard for the permanent repair of distribution gas fittings to include cracked or damage pipe joints, split collars, branch saddle connections, flange joints, couplings, under pressure tees, cap ends, syphons and valves operating at pressures up to 0.75 bar.

Encapsulation special pipe fitting repair kit fully approved to BGC/PS/LC8 part 1 and the DVGW European standard for the permanent repair of distribution gas fittings to include cracked or damaged pipe joints, split collars, branch saddle connections, flange joints, couplings, under pressure tees, cap ends, syphons and valves operating at pressures up to 2.00 bar.